Pyrolysis-Gas Chromatography-Mass Spectrometry (Py-GC-MS) Model:Pyrolyzer-Gas Chromatography-Mass Spectrometry (Py-GC-MS)

Pyrolysis-Gas Chromatography-Mass Spectrometry (Py-GC/MS) is a technique to analyze the chemical structure and composition of polymer samples in any form, including insoluble and infusible three-dimensional cross-linked structures. Since this technique only requires very small amounts of samples without pretreatment and provides unique information that is otherwise difficult to obtain with other analytical techniques, it is an essential analytical technique for polymer characterization.

-

∎ Features

Significant improvement in furnace performance (rapid heating/rapid cooling)

Rapid heating and cooling is achieved by employing a ceramic heater with low thermal mass. This excellent heater features a wide temperature range: from ambient to 1050 ºC.High performance and high reliability (pyrogram, inertness, analysis of high boiling point compounds)

The performance is guaranteed to meet the stated specifications such as the thermogram of evolved gas analysis and the pyrogram of instantaneous pyrolysis analysis.Any sample form for analysis

The evolved gas analysis, thermal desorption, flash pyrolysis, double-shot, and heart-cut EGA-GC/MS methods can be used to characterize polymer samples from multiple viewpoints.- Operating mechanism of EGA (Evolved Gas Analysis)

- Operating mechanism of Single-Shot Analysis

- Operating mechanism of Double-Shot Analysis

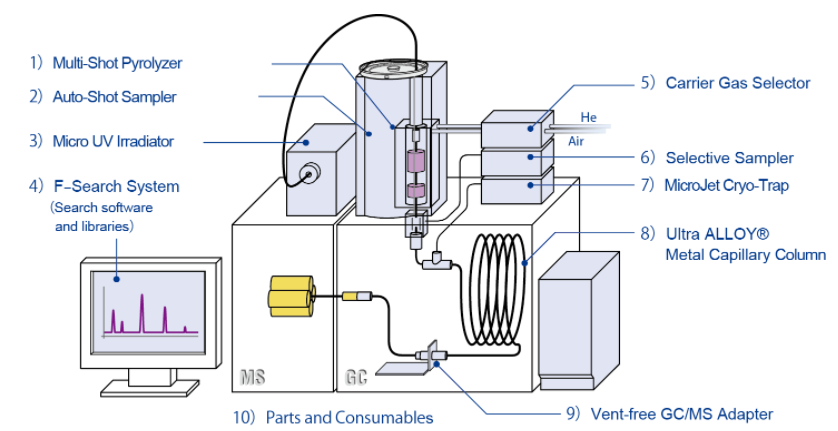

The Multi-Functional Pyrolysis System can be used in a variety of applications by combining the pyrolyzer with optional peripheral accessories

- Auto-Shot Sampler

- Micro UV Irradiator

- F-Search System

- Multi-Functional Splitless Sampler

- Carrier Gas Selector

- Selective Sampler

- MicroJet Cryo-Trap

- Ultra ALLOY®Metal Capillary Column

- Vent-free GC/MS Adapter

- Cryogenic Mill

-

PY-3030D Specification

Items Specification Dimensions (WxHxD)2: 76 (W) x 143 (D) x 215 (H) mm Weight: 1.6kg Required Power 100-115Vac (400W max) Furnace temperature control range room temperature +10 to 1050 ºC (1 ºC increment) Temperature stability: within ± 0.1 ºC Heating furnace heating rate Max. 600 ºC / min (every 1 ºC / min) Interface temperature control range 40 to 450 ºC (1 ºC increment) Performance guarantee

(polystyrene thermogram with MS detector)Peak top temperature reproducibility is 0.3 % or less (RSD) Performance guarantee

(polystyrene pyrogram with MS detector)Reproducibility of the trimer and internal standard ratio is 2 % or less (RSD) Requirements gas chromatograph (with split/splitless inlet), etc. -

- Polymer: material identification, quality control

- Additives: surfactants, plasticizers, residual monomer substances, solvents, volatile catalysts, impurity identification

- Plastic: resin, plasticizer, molding agent, UV-antioxidant, film, foam, gel

- Coatings: dyes, solvents, desiccants, film forming agents

- Fiber: blended fiber, natural fiber, non-woven fabric

- Elastic materials: sulfur compounds, natural rubber, synthetic materials, silicone

- Adhesive: hot melt adhesive, anaerobic materials, acrylic, epoxy resin

- High ink: dye, resin, solvent, defoaming agent, wax, photocopy toner

- Food Flavors: Regulations restrict testing of organic chemical substances