The Thermal Desorption Analyzer IH-TDS1700 Model:IH-TDS1700

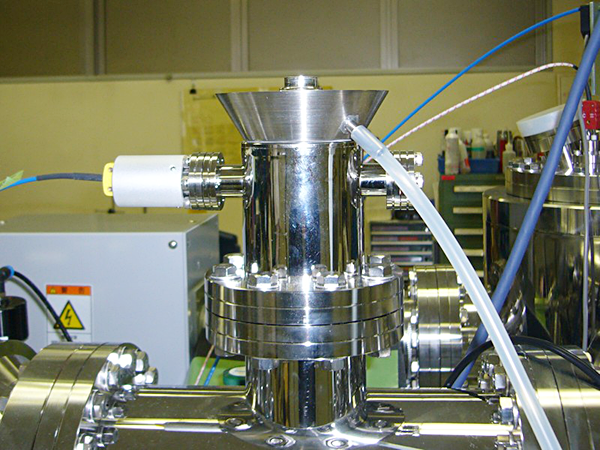

The thermal desorption analyzer IH-TDS1700 heats samples in an ultra-high vacuum using electromagnetic induction heating, and utilizes a quadrupole mass spectrometer (QMS) for real-time observation of molecules desorbed from the sample.The ultra-high vacuum enables high-sensitivity measurements with low background. Side reactions between the atmosphere and generated gases are suppressed, so the desorbed molecules from the sample can be observed under optimal conditions.

-

∎ Features

The thermal desorption analyzer IH-TDS1700 heats samples in an ultra-high vacuum using electromagnetic induction heating, and utilizes a quadrupole mass spectrometer (QMS) for real-time observation of molecules desorbed from the sample. The ultra-high vacuum enables high-sensitivity measurements with low background. Side reactions between the atmosphere and generated gases are suppressed, so the desorbed molecules from the sample can be observed under optimal conditions.

For metal samples with good heating efficiency, heating to temperatures above 1700 °C is possible. In addition, low temperature TDS measurement of diffusible hydrogen in steel, a cause of hydrogen embrittlement in steel materials, is also possible.The load-lock chamber

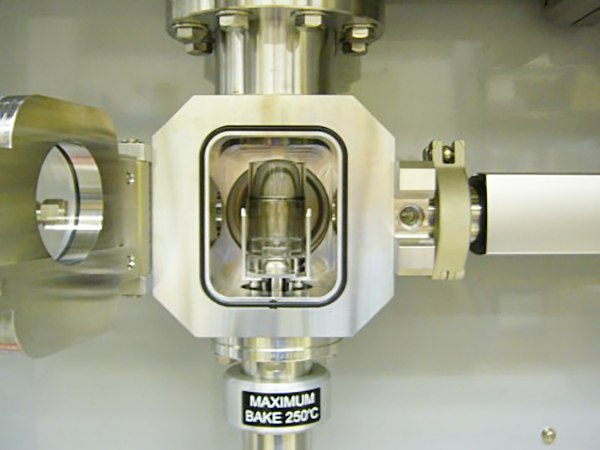

The load-lock chamber is essential for achieving high sensitivity and high-efficiency (high throughput) measurement. Our load-lock chamber and sample transfer mechanism enable quick insertion of only the sample into the analysis chamber under an ultra-high vacuum.

If there is no load-lock chamber, it is necessary to expose the analysis chamber to ordinary atmosphere each time the sample is exchanged. A large amount of air (mainly water) is drawn into the analysis chamber when it is exposed to ordinary atmosphere, making it necessary to perform evacuation for a long time to return to a suitable vacuum level.

Because it is possible to measure a cooled steel specimen, diffused hydrogen is prevented from escaping and can be quantified with high accuracy, even the diffusible hydrogen of BCC steel, which has a large hydrogen diffusion coefficient.

Low-temperature TDS measurement of diffusible hydrogen in steel

If frost adheres to the cooled steel specimen, the desorption of this frost can affect the hydrogen signal and cause an error in the measurement of the diffusible hydrogen (the uncertainty increases). The cold trap (option) of IH-TDS1700 can trap frost to minimize the influence of the frost, enabling acquisition of desorption spectra of diffusible hydrogen with less distortion.

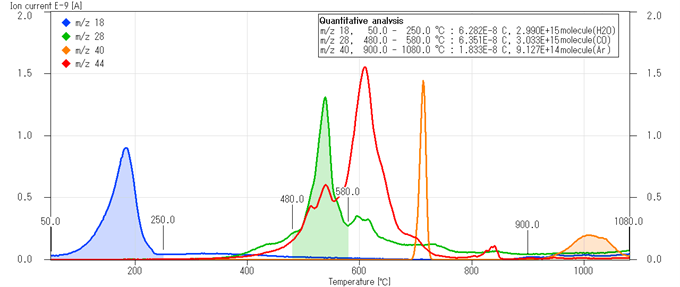

Quantification of desorbed gases

The data processing program enables quantitative analysis of the desorbed gases. To perform quantitative analysis of the desorbed gases, it is necessary to regularly calibrate the sensitivity of the mass spectrometer.

Sensitivity calibration using standard leaks requires preparation of an expensive standard leak for each type of gas, and the calibration procedure is time-consuming. In addition, strict health and safety management is required when standard leaks of poisonous gases are used.

The current quantification program enables quicker, easier, and safer quantitative analysis of the desorbed gases than the method using calibration with standard leaks. Highly accurate results can be obtained simply by periodically measuring the NIST-traceable hydrogen standard sample produced by ESCO. The sensitivity correction method we have developed can correct the sensitivity even for gases other than hydrogen, and it has been verified that the results obtained are in good agreement with quantitative results obtained using calibration with a standard leak according to the National Institute of Advanced Industrial Science and Technology (AIST) standards.

-

Items Specification Vacuum pressure Main chamber 1×10-7 Sample size 20mm diameter x 40mm length Temperature range Low-temp mode:-50 to 800°C,maximum 1000°C

High-temp mode:RT to 1700°C or higherTemperature increasing rate 1-180℃/min Detector QMS Sensitivity Ar 1*1011 Ar/s (S/N=3) Software TDS measurement, Data Viewer, Quick CSV -

- Quantitative Analysis of Diffusible Hydrogen in Metals

- Metal molten gas analysis

- Ceramic sintering reaction gas analysis

- Glass dissolved gas analysis